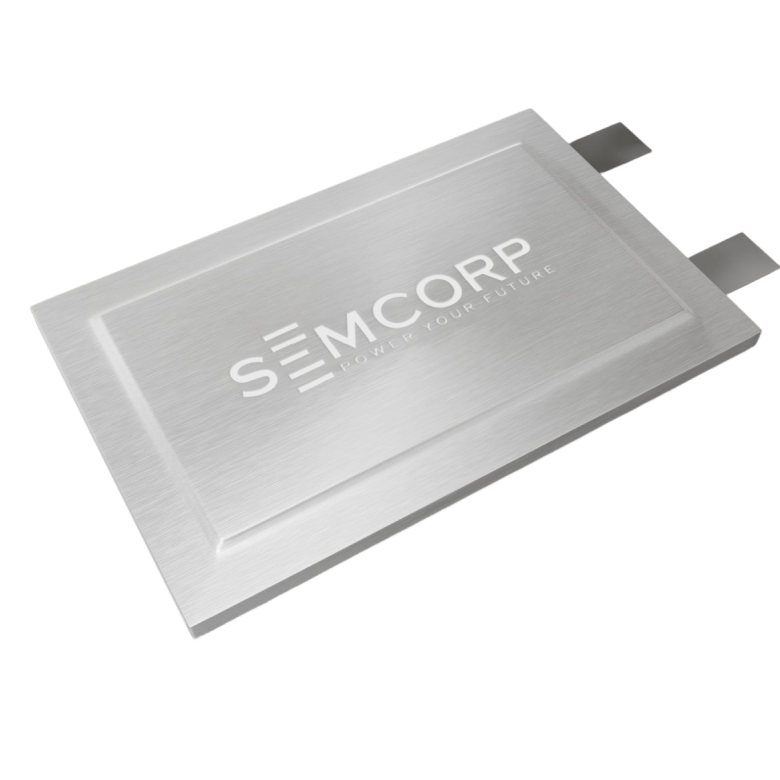

Al-Plastic Film

-

1

-

2

-

3

-

Al-Plastic Film

Al-Plastic Film -

Anode

Anode -

cathode

cathode

Soft-pack lithium-ion battery packaging material is a multi-layer composite material usually bonded together by PET(polyethylene terephthalate), NY(nylon), aluminum foil and CPP(cast polypropylene) via dry or thermal methods.

Characterized by lightweight, easy encapsulation, formability and durable use, it is a packaging material fit for high energy density cells.

Application

-

Power lithium-ion battery and energy storage lithium-ion battery

Performance requirements for batteries include endurance mileage, safety, and durability. SEMCORP can offer and develop, based on the requirements of soft-pack lithium-ion battery manufacturer customers, aluminum plastic film products with high formability, high insulation and heat resistance and long dutability, to meet the requirements of customers in various scenarios.

-

Lithium-ion battery for consumer electronics

Batteries for consumer electronic products have high requirements in lightweight, differentiation, high energy density, and easy design of appearance and structure of soft-packaging. Energy SEMCORP can provide and customize thin aluminum plastic film products based on customer needs.

Products

-

Dry aluminum plastic film

Dry aluminum plastic filmProduction techniques of coating and dry-lamination are adopted for the processing. They are characterized by a certain advantage in formability and the inner-layer insulation. It is used in consumer soft-pack battery (aluminum plastic film specification≤113μm), power soft-pack battery and energy storage soft-pack battery (aluminum plastic film specification≥153μm).

-

Thermal aluminum plastic film

Thermal aluminum plastic filmProduction techniques of coating, dry-lamination and extrusion-lamination are adopted for the processing. They are characterized by a certain advantage in heat-resistance and cost. It is used in consumer soft-pack battery (aluminum plastic film specification≤113μm), power soft-pack battery and energy storage soft-pack battery (aluminum plastic film specification≥153μm).

Advantage

-

High Formability

High FormabilityAn increase of 50% in formability compared with conventional structural products

Increased energy density of battery

Battery pack strength is also enhanced and is able to resist certain impacts.

-

Long Durability

Long DurabilityThe expected duration is over 10 years.

-

High Insulation

High InsulationThe formulation design of the inner layer improves the insulation of the inner materials and prevents insulation corrosion after encapsulation into batteries.

-

High Heat-Resistance

High Heat-ResistanceHeat resistance is enhanced through the formulation design of the inner layer.

Related Enterprises